Captain William Hicks, USN Ret.

Introduction

Introduction

This is the first in a series of articles about the evolution of nuclear weapons during the Cold War. This series begins with some basic information about the physics of nuclear weapons, management of the program, weapons production, and a brief description of the U.S. nuclear weapons industrial complex. There is an old saying that every war begins

with the weapons of the previous war. This was never truer than in the case of the Cold War.

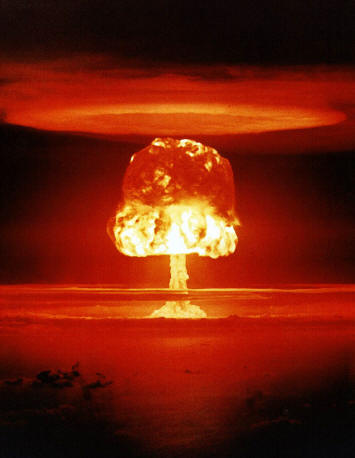

A war that lasted for over four decades with the images and legacy of the of World War II at Hiroshima and Nagasaki . The Cold War was a war that neither side really wanted to happen. But, It was a war of constant preparation for this awful possibility. A war where the concept of "Mutual Assured Destruction" (MAD) was very real. Yes, you had to be mad

to use a nuclear weapon, but you also had to be ever ready to do so. That was what the Cold War was all about.

Evolution of nuclear weapons complex during the cold war

At the end of WW II, the significance of nuclear weapons was clear—both the massive destructive power they presented as well as the dangers to life on the planet if proliferation were not controlled. It was also clear that the genie was out of the bottle and could not be returned or ignored. The US had a monopoly, but for how long and to what purpose.

How would the monopoly be managed? What was the future of nuclear weapons moving forward?

The purpose for this short discussion is to explore how the US dealt with the challenges of nuclear weapons during the cold war and the legacy remaining at the end of the cold war. In an overarching sense, the discussion will focus on four areas: How the nuclear weapons program was managed; how research and development evolved; the creation of the

industrial infrastructure to meet the demands for nuclear weapons; and finally the legacy after the cold war ended.

The physics and basics of nuclear weapons

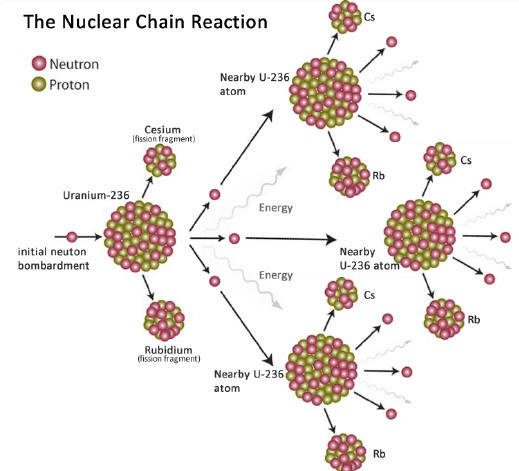

Research during the 1930’s identified the phenomena that when an atom of Uranium 235 absorbed a neutron, it split into two smaller atoms, released a significant amount of energy, and additional neutrons. It was theorized that if this phenomena could be

harnessed and managed, it had the potential to produce a large amount of energy, either explosively or as a source of power.

Research during the 1930’s identified the phenomena that when an atom of Uranium 235 absorbed a neutron, it split into two smaller atoms, released a significant amount of energy, and additional neutrons. It was theorized that if this phenomena could be

harnessed and managed, it had the potential to produce a large amount of energy, either explosively or as a source of power.

Further research identified a second isotope of uranium, U233 and a man-made isotope, Plutonium 239 (PU239) which also split when a neutron was absorbed. The splitting of the atom is known as Fission. Materials that will fission are called fissile material. When the explosive energy of a nuclear weapon is solely from fission, it is a fission bomb. Both

bombs dropped to end WWII were fission bombs, one using U235 and the other using Pu239 as the fissile materials.

Research following WWII identified that significant amounts of energy could also be released if two light elements are forcibly combined into a single heavier element. In current US nuclear weapon design, two isotopes of Hydrogen, H2 (deuterium) and H3 (Tritium) are forced together under high heat and pressure and form Helium 4 (He4) plus a neutron and

a large amount of energy. The process is known as fusion. In practice, the pressure and energy to initiate and support a fusion explosion in a bomb is provided by a fission explosion.

In order to achieve a fission explosion, there must be enough fissile material in a physical configuration to sustain the individual fission events in a chain reaction which occurs when the available neutrons from one fission event are adequate to create another fission event. The material and the physical configuration is called a critical mass. If

the intent is to cause an explosive event, many fission events must occur in a very short period of time. If the intent is to product power from the fission reaction, the chain reaction is slower and more controlled.

While the physics of nuclear weapons may seem relatively simple, the design and engineering required to create the conditions that will result in a nuclear explosion is much more complex than the basic physics. As discussed later, there were many different nuclear weapons designs in the US stockpile but they all had several basic engineering elements

in common: The fissile material is maintained in a subcritical configuration until the explosion is initiated at which point it is transformed into a critical mass, usually through controlled and shaped chemical explosives.

In a plutonium based fission weapon, the mass of plutonium is called a pit. The pit is normally a sphere with a hollow center that can be compressed into a critical mass using shaped explosives. In a uranium weapon, the critical mass is created by forcing one piece of fissile material into a second donut shaped piece of fissile material. This weapon

design is known as a gun barrel. To enable the rapid fission events necessary to create an explosive force, an external source of neutrons is provided.

The design of the neutron sources evolved over the years. To create a fusion weapon (hydrogen bomb in the popular vernacular), a source of tritium and deuterium is required to be integral to the fission explosion. Additional elements include fusing which controls when the explosive event occurs, safety and security elements which prevents nuclear

explosions when not desired, and delivery element which support delivering the weapon to the desired target. Thus, the practical engineering and design of nuclear weapons is much more complex and challenging than the physics of nuclear explosions.

The Management of the Nuclear Weapons Program

The development and production of the first nuclear weapons was managed by the Army within the Manhattan Engineering District. At the end of the war, it was apparent that the development and stockpiling of nuclear weapons would continue as an element of national defense. It

was also apparent that nuclear energy had uses and benefits beyond weapons.

The development and production of the first nuclear weapons was managed by the Army within the Manhattan Engineering District. At the end of the war, it was apparent that the development and stockpiling of nuclear weapons would continue as an element of national defense. It

was also apparent that nuclear energy had uses and benefits beyond weapons.

The Atomic Energy Act of 1946 was signed by President Truman on August 1, 1946. The act provided that the activities to exploit the benefits of atomic energy as well as development of nuclear weapons would be managed by the Atomic Energy commission (AEC). The AEC consisted of 5 commissioners selected by the President. The military as a customer of the

AEC was linked by the military liaison committee. Congressional oversight was via a joint Committee on Atomic Energy.

The AEC followed the model used by the Manhattan district which was a small organization to set policy and requirements which contracted with the most competent and experienced industrial and educational institutions in the nation to manage the individual elements of the nuclear energy infrastructure. The nuclear infrastructure followed the GOCO

(Government Owned, Contractor Operated) model. The AEC acted as the regulator of the nuclear infrastructure as well as the customer for the products from the infrastructure.

The inherent conflict with the owner, regulator, and customer residing within the same entity was never fully resolved. For commercial nuclear energy, the regulatory function was separated from the research and development function by formation of the Nuclear Regulatory Commission (NRC) to regulate the commercial nuclear industry. The AEC was also

responsible for interactions with congress to gain the funds for the enterprise. The justification for funding of AEC activities in support of the nuclear weapons programs was reinforced by input from the Department of Defense as the primary customer.

In 1975, the AEC was split into the Energy Research and Development Administration (ERDA) and the NRC. ERDA retained all the assets and responsibilities associated with the nuclear weapons programs. In 1977, ERDA was combined with the Federal Energy Administration to become the Department of Energy (DOE), a cabinet level department. Throughout the

evolution, the management structure and methodology for the nuclear weapons program remained relatively constant.

The AEC/ERDA/DOE managed the nuclear weapons complex with a headquarters organization supported by a series of field or operational offices located at each production, test, or research site across the complex. The organization was primarily focused on contract administration and overall direction to the contractors with limited involvement in the day

to day management of the individual activities at the sites. The initial strategy remained as it was in the Manhattan Project to persuade the most experienced and technically competent companies to manage the individual operations as a patriotic duty on a cost plus basis with in some cases minimal fees. In a similar strategy, the research laboratories were operated by the

leading universities as a non-profit laboratory.

As the years passed and the activities within the nuclear weapons complex became more transparent, the strategy became more difficult to maintain. Profits became more important to the industrial partners. Contractual cost containment became more important to DOE. And, the regulators and interveners became more intrusive to the operations at the

individual sites. This transition continues to play out today as DOE struggles with the conflicts and challenges of being the owner, regulator, and customer of the complex.

Production of the nuclear weapons

The Manhattan Project managed the research and production of the first few nuclear weapons as basically a research project in which the production sites were developed as the research determined a need for the products. Thus much of the research and production was commingled at the same sites. Production tasks were accomplished by the research

community at sites such as Los Alamos, NM; Oak Ridge, TN; and Argonne near Chicago, IL.

Following the end of WW II, the military value of nuclear weapons became a subject of study by all services. Each service wanted an inventory to suit its particular strategies. The wish lists included large numbers of many types of nuclear weapons from very large bombs to small man-portable satchel charges. It was clear that meeting these demands would

require a significant increase in the research and development portion of the nuclear weapons complex as well as a significant increase in the industrial production portion of the complex. It was also determined that production efforts should be separate from the research efforts.

The nuclear weapons supply chain contains many different products. Uranium is the basic material. Uranium occurs naturally and must be mined from the earth. Once uranium ore is available it must be processed into a form that can then be enriched to increase the percentage of fissile material. Only 0.7% of natural uranium is the fissile element U235.

Enrichment is necessary to increase this percentage from 3.5% to 97% depending on the end-use for the uranium. The feedstock to the enrichment process is normally gaseous.

Several different enrichment processes have evolved. The initial process was the calutron which was developed and installed at Oak Ridge. By the end of the war, gaseous diffusion was the more rapid and preferred enrichment method. Today centrifuges are the enrichment method of choice. The use of centrifuges has been discussed recently in relation to

the Iranian actions to enrich uranium.

Once PU239 has been produced during reactor operation, it must be separated from the other fission products and materials in the reactor core. This is both a complex chemistry problem as well as a hazardous radioactive process. In practice the PU239 separation processes were conducted in remotely controlled, shielded facilities commonly known as

canyons.

Remote operations were generally not computerized robots, but directly operated manual manipulators viewed through shielded windows and mirrors. The waste byproducts from the separation process were very toxic and highly radioactive liquid waste streams. No effort was

made to develop a permanent dispose process for these hazardous wastes. As an immediate solution, they were stored in underground tanks until a permanent disposal process could be developed. These liquid wastes are a challenging part of the legacy of the cold war nuclear weapons enterprise.

Remote operations were generally not computerized robots, but directly operated manual manipulators viewed through shielded windows and mirrors. The waste byproducts from the separation process were very toxic and highly radioactive liquid waste streams. No effort was

made to develop a permanent dispose process for these hazardous wastes. As an immediate solution, they were stored in underground tanks until a permanent disposal process could be developed. These liquid wastes are a challenging part of the legacy of the cold war nuclear weapons enterprise.

Once the PU239 was extracted as a metal, it was formed into the desired shape to support the weapon design. The bomb designs required many other materials and components, all of which were provided by the AEC industrial complex. These materials and components spanned the spectrum from materials such as deuterium and tritium (isotopes of hydrogen),

lithium, and Beryllium to very precise explosives and the timers to control them to the cases in which the bomb components and the whole bombs were packaged and the delivery items such as parachutes and proximity fuses to trigger the explosion.

The nuclear weapons stockpile grew slowly until 1950 when it became clear that the Soviet Union had developed nuclear weapons and the cold war was becoming more intense. In that period, nuclear weapons with many different sizes and uses had been developed which increased the complexity of the work of the nuclear weapons complex. During this period the

strategy for survivability was being developed which meant that many weapons widely dispersed were required. It also lead to decisions to disperse the facilities of the nuclear weapons complex such that loss of one site would not stop production.

The following specific facts are provided by Charles Loeber in his book describing the history of the nuclear weapons complex: Stockpile grew from 13 weapons in 1947 to 1169 in 1953 to 22,229 in 1961. The production rate exceeded 7,000 weapons per year in 1959 and 1960. Between 1950 and 1963, 39 new weapons systems were added to the stockpile.

Employees both contractor and government grew from approximately 55,000 in 1947 to 142,000 in 1952. In total, the United States has produced about 70,000 nuclear weapons of 72 major types since their invention. At the end of the Cold War in 1991 the United States had an active arsenal of some 23,000 weapons of 26 major types.

The nuclear weapons industrial complex

The following discussion reflects the nuclear weapons complex in the mid 1980’s. The pressures and dynamics discussed above drove many of the decisions regarding sites and functions across the complex. In the beginning, almost every site of the industrial complex was operated by an industrial company with expertise in the specific area of manufacture.

Many companies agreed to operate the facilities as a patriotic duty. Over time as discussed above this situation changed to one in which contractor selection was by competitive bidding and the sites were operated by contractor teams as for-profit activities.

The activities at Y-12 include fabrication of many different enriched and depleted uranium parts for various parts of the weapon. In addition, uranium scraps are recovered and uranium contaminated waste is treated to save the uranium that is included in the waste such as on wipe rags or forming molds. The stockpile of enriched uranium is also stored and

managed at Y-12.

During the life of the nuclear weapons complex, uranium fabrication occurred at other sites such as Rocky Flats, Mound and Savannah River but it eventually all consolidated at Y-12. In addition, Y-12 is responsible for the assembly and disassembly of the secondary part of the weapons. The secondary contains no explosives or plutonium. It is the part of the

weapon in which the fusion reaction occurs. While Y-12 assembles and disassembles the secondary, the work of final assembly or initial disassembly of the full weapon occurs at Pantex.

Moving a B-51 nuclear bomb at Pantex

Several other sites were established to assemble, disassemble, modify, or evaluate nuclear weapons. These sites included the Clarksville Modification Center located on Fort Campbell Military reservation in Clarksville Tennessee where retired weapons were disassembled, the Medina Modification Center in San Antonio Texas on Lackland Air Force Base conducted

weapon modification and stockpile evaluations, and Picatinny Arsenal in Morris County, New Jersey which produced adapter kits for the army nuclear weapons. Eventually the functions of these sites were transitioned to Pantex and Y-12.

Neutron generators are an important part of the weapon since the initial burst of neutrons is what initiates the rapid supercritical condition and significant release of energy that is the nuclear explosion. In the initial weapons, neutron generation was a chemical process with radioactive materials that required frequent replacement and were difficult to

handle. Subsequent development provided neutron generators that were stable and not subject to frequent changes. The neutron generators were manufactured at the Pinellas Plant near St. Petersburg, Florida. Pinellas also produced other electronic components. Following closure of the Pinellas plant in 1994, Neutron generator manufacture was transferred to Sandia in Albuquerque

N.M.

Nuclear weapons contain many non-nuclear electrical, mechanical, rubber, and plastic components such as switches, timers, seals, and connectors which must be manufactured with precision, many from classified designs. The manufacture of these vital components is concentrated at the Kansas City Plant in Kansas City Missouri.

While the components that enable the nuclear explosive capability of the weapon are the essential part, the packaging for those components and the delivery devices such as proximity fuses or parachutes are necessary to have a weapon. Sandia site in Albuquerque, New Mexico was both a laboratory to develop these non-nuclear packaging components as well as to

manufactures many of them. Thus Sandia is both a production site and a research center which will be discussed in the next section. Sandia was the location at which many of the precise electronic chips that were part of the weapon were designed and manufactured.

As the dispersed nuclear weapons infrastructure developed and the volume of production escalated, a significant transport capability was required. Initially, a combination of commercial and government resources were utilized to transport the nuclear weapons, nuclear weapon components and special nuclear material. With the rise of terrorism and acts of violence

in the late 1960Õs a review resulted in a new series of regulations and equipment and the establishment of the Office of Secure Transportation (OST) within the Department of Energy.

The OST modified and redesigned transportation equipment to incorporate features that effectively enhanced self-protection and deny unauthorized access to the materials being transported. OST manages a fleet of transportation assets, couriers, and a comprehensive operations organization from the Albuquerque Operations Office in Albuquerque New Mexico. OST has

accumulated over 100 million miles while transporting nuclear weapons materials without any loss, release of radioactive material, or fatal accidents.

Nuclear Weapons Research and Testing

During the Manhattan Project, nuclear research and nuclear weapons development including the production of the first weapons were accomplished at integrated sites such as Oak Ridge, Los Alamos, Chicago, and Hanford. As the post war nuclear weapons complex developed, it was determined that research, development, and testing should be separate from production

activities. In this section, I will discuss the research and development and testing challenges and infrastructure developed during the cold war in support of nuclear weapons development, enhancements, safety, and reliability.

Research associated with nuclear weapons looked in many different directions. There was a desire to make the weapons smaller so that they could be accommodated on a large number of delivery mechanisms from large bombers to man-carried satchels, and ultimately atop ICBMs. Requirements for different delivery required different packaging and delivery devices such

as parachutes and mating packages for torpedoes, rockets, and missiles.

Research was also required to achieve both larger and smaller explosive yields. There was even a desire to set the size of the yield at the time of delivery. One of the significant advances was the discovery and development of fusion weapons, which used the fission explosion to trigger the much larger fusion explosion. Weapons explosive power with fusion

weapons could exceed 50 Megatons (of TNT equivalent explosive power). On the other end, weapons explosive yield less than a kiloton was also developed. These weapons were much smaller than those which ended WWII and could be used in close proximity to friendly forces or for focused purposes. As noted above in one 13-year period, 39 new weapons systems were developed by the

research complex and introduced into the inventory. Every one of these new weapons systems required actual testing to certify the design assumptions prior to being placed into service.

Maintenance of the weapons in the stockpile became a research issue. The initial nuclear weapons had some components with very limited lifetimes which meant frequent maintenance actions which usually required returning the weapon to the weapons complex or very specialized training and facilities at the DOD depots. The goal was a nuclear weapon that could be

placed in storage or in a ready status for a long period of time without interim maintenance.

Safety and Security was a key issue for the research community. The initial nuclear weapons were essentially assembled just prior to use. That was clearly not a desirable situation for the various military uses envisioned for nuclear weapons. Rather the weapon should be fully assembled while in storage or being transported for use, but safe from inadvertent

explosion due to mishandling or stupidity on the part of the handlers, or accidents such as plane crashes or depot accidents. Having the weapons fall into enemy hands was also a risk that was mitigated by the safety and security design features in the weapons. In fact, the features that made the weapons inert until just before use are some of the most highly classified

features of the weapon design.

The use of nuclear warheads on ballistic missiles provided another research and design challenge to ensure the continuing effectiveness of the weapons. When in ballistic flight beyond the atmosphere, the weapons were subject to excessive radiation. In addition, a potential defense against a missile in flight was another nuclear explosion that would release an

intense burst of electromagnetic radiation. Finally, the ballistic missile launch and reentry produced great acceleration and deceleration forces on the weapons. The designers were challenged to produce a weapon that would remain effective in this severe environment.

An important task for the research community was to certify the reliability of the nuclear weapons stockpile on an annual basis. For many years, this certification was based on the results of actual weapons testing. Following the testing moratorium in 1992, the basis for the certification became computer simulations of the weapons performance. Variables such

as radioactive decay of the fissionable material and aging of the weapon components, both electrical/electronic and mechanical such as high explosives and component seals required consideration when determining the continued reliability of a weapon which may have been in the stockpile for many years. To deal with all the possible variables significant computing power was

required. Thus the weapons laboratories acquired or developed some of the most powerful computers in the world. In addition, the laboratories carried out cutting edge research into the aging properties of the unique materials used in the various weapons systems.

The testing moratorium had another consequence in that without testing it was not possible to develop any new weapons systems. This required that existing weapons systems remain in the stockpile longer than the initial design life. The laboratories were tasked with providing the basis and necessary modifications to affect a lifetime extension for some of the

weapons systems.

Nuclear Weapons Complex laboratory infrastructure

Three major laboratories support the nuclear weapons complex: Los Alamos National Laboratory (LANL) in Los Alamos, New Mexico; Sandia National Laboratory (SNL) in Albuquerque, New Mexico; and Lawrence Livermore National Laboratory (LLNL) in Livermore, California. Additional DOE funded laboratories provide specialized support to the nuclear weapons complex.

Savannah River Test Center supported the reactors and separation processes used at Savannah River.

Oak Ridge National Laboratory was the site of an early Manhattan Project graphite reactor and continued to support the nuclear weapons complex with specialized research but not weapon design support. Pacific Northwest Laboratory in Richland, Washington supported the processes and reactors at Hanford site. Argonne National Laboratory located in Downers Grove

Township, Du Page County, Illinois near Chicago was established during the Manhattan Project as the location for the research by Enrico Fermi into nuclear reactor designs after the initial reactor was moved from beneath Stagg field on the campus of the University of Chicago. It has developed into a multipurpose laboratory including reactor related research with limited role

in the nuclear weapons complex. Argonne holds the distinction of being the first laboratory designated as a national lab on July 1, 1946.

LANL was established in 1942 as the top secret location at which the nuclear bomb would be developed. It is located on a high mesa north of Santa Fe, NM. LANL was operated from the beginning and throughout the cold war by the University of California. LANL along with LLNL developed and refined the different weapons systems that were and are included in the

nation's nuclear weapon stockpile. LANL was responsible for much of the research discussed above to improve and modify the individual weapons systems.

LANL was also a full partner in the nuclear test program with much of the actual analysis from the results of nuclear tests being conducted at LANL. LANL had a detachment at the test site where they assembled the actual test weapons and analyzed some of the quick look data. LANL also maintains a detachment at the weapon assembly plant to oversee and advise on

the assembly of weapons systems for which they had design responsibility. During the cold war, LANL diversified the scope of research into medical and environmental areas. Following the end of the cold war, LANL went through a process of intense scientific diversification in their research programs to adapt to the changing political conditions that no longer required as much

research towards developing new nuclear weapons and has led the lab to increase research for 'non-war' science and technology. LANL has one of the supercomputers that are used to simulate nuclear explosions and to support the assessment of the viability of the nuclear weapons stockpile as part of the annual certification of stockpile reliability.